Description

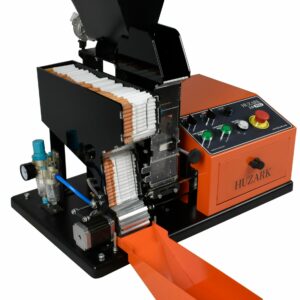

The Cigarette Filling Machine operates on both electrical and pneumatic power sources, requiring an 8-bar compressor for optimal performance. Crafted with precision from high-quality stainless steel components, its durability ensures a virtually limitless service life.

Featuring three modes – single loading, automatic modes I and II – our Injector delivers flawless cigarette filling, courtesy of a piston mechanism that guarantees perfect results, even with intensive use for up to a month. The end product closely matches store-bought cigarettes.

Adaptable to various tobacco types, the Injector is also soundproofed for quieter operation. Additionally, it includes a convenient tank for storing ready-made cigarettes, enhancing user convenience.

Product Specifications:

- Efficiency: 70 pieces per minute

- Designed to inject shell casings with filters, 15mm in diameter, rolling: 8mm

- Infinitely adjustable shell casings injection

- Shell casings tank capacity: 600 pieces

- Soundproofed design

- 8-bar compressor required

- Power: 230V, 8-bar compressed air

- Weight: 35kg

- Size: 70x41x44cm

Huzark 4.0 – a next‑gen cigarette filling machine

With an output of 70 cigarettes per minute, the 2024 Huzark 4.0 pushes productivity into true industrial territory. Yet, it stays compact enough for workbench installation. Every stroke of its stainless‑steel piston produces a uniform pack density, so the finished cigarettes burn evenly and draw smoothly – a signature feature of a professional cigarette making machine.

Precision that protects flavor

Fine‑tuning the infinitely adjustable injection system takes seconds. Whether you run dry strands or richer blends, the machine prevents over‑compression, preserving essential oils and flavor notes. For operators juggling multiple recipes, the digital dial saves preferred settings, cutting changeover time between batches.

Day‑to‑day wins with Huzark cigarette filler

- Large hopper, fewer stops – a 600‑tube reservoir keeps the line moving, allowing a single operator to monitor production for an entire shift.

- Quiet, safe work area – integrated sound‑dampening reduces noise fatigue and meets common workplace decibel guidelines.

- Tool‑free maintenance – quick‑release panels give instant access to the feed path; a daily wipe‑down is usually all that’s needed to keep residue at bay.

Plug‑and‑play installation

The 4.0’s 35 kg frame and 70 × 41 × 44 cm footprint slide easily into existing lines. Just connect an 8‑bar compressor, plug in the 230‑V lead, and the cigarette filling machine is ready to earn its keep – no custom wiring or extra regulators required.

Professional cigarette making machine built for expansion

Planning to double output next year? Pair two Huzark 4.0 units side by side. The synchronized auto‑mode keeps pacing consistent, so scaling up is a matter of adding machines, not redesigning the line.

Ready to upgrade your production?

If reliability, speed, and precise control top your checklist for a cigarette filler, the Huzark 4.0 model 2024 delivers a measurable edge. Contact our technical team for setup advice, training packages, and multi‑unit pricing, and turn 70‑per‑minute efficiency into a lasting advantage on your production floor.

Reviews

There are no reviews yet.