Description

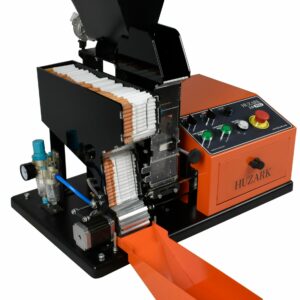

The device is powered electrically and pneumatically. You must have an8 bar compressor. Cigarette filling machine Huzark is made of high-quality components made of stainless steel which means that its services life is practically unlimited.

Our device has 3 modes, single loading and automatic mode I and II. One of the advantages of our Injector is a piston that fills cigarettes perfectly and provides intensive work for up to a month. The received product practically does not differ from that available in the store.

Cigarette filling machine Huzark is adapted to handle various types of tobacco and has been additionally soundproofed. What is more, our device has a tank for ready-made cigarettes, which makes it very easy to use.

Product Details:

- Efficiency of 60 pieces per minute

- Adapted to inject the shell casings with filter, 15mm, rolling: 8mm

- Infinitely adjustable shell casings injection.

- Shell casings tank capacity: 600 pieces

- Soundproofed

- 8 bar compressor required

- Power: 230 v, 8bar compressed air

- Weight: 35kg

- Size: 70x41x44cm

Reasons to choose the Huzark 3.0 cigarette filling machine

Investing in a reliable cigarette filling machine is about more than speed alone. With its 60‑piece‑per‑minute output, the Huzark 3.0 delivers consistent density in every tube, helping you build a reputation for premium quality. Because the entire feed path is stainless steel, residue buildup is minimal, so routine clean‑downs take only minutes – a deal for businesses that can’t afford lengthy shutdowns.

Built for busy facilities – yet compact

Weighing just 35 kg, our professional cigarette making machine takes up little floor space and can be moved between workstations when production needs to change. The 600‑tube hopper keeps the line moving, while the sound‑dampened cabinet protects staff from constant compressor noise. All controls are grouped on a single front panel, so operators can adjust injection speed or switch between single‑load and auto modes – without interrupting the run.

Optimize labor and cut costs with our professional cigarette making machine

Perfectly packed cigarettes reduce waste from cracked papers or uneven burns, saving money on raw materials. Since one operator can oversee multiple Huzark units, labor costs drop, and output scales quickly. The 230‑V power requirement means no special wiring – simply plug in, connect an 8‑bar compressor, and start filling.

Versatile cigarette filler for multiple blends

Whether you work with bright or darker tobacco cuts, the infinitely adjustable injection system handles varying moisture levels with ease. Fine‑tune the piston stroke to achieve the draw resistance your customers prefer. Because the machine never over‑compresses, delicate aromas remain intact – and match the experience of store‑bought brands.

Maintenance made simple

Daily upkeep involves clearing the feed tray and giving the stainless chamber a quick wipe – no special tools needed. A quarterly check of the pneumatic seals is typically all it takes to keep this cigarette filling machine running at peak efficiency for years. That’s what smart investment is – you pay once and keep the production going.

Elevate your production

If you’re upgrading from a manual cigarette filler or adding capacity to a larger line, the Huzark 3.0 is a proven, cost‑effective step forward. Reach out today for lead times, financing options, and on‑site training packages, and turn consistent 60‑per‑minute performance into a competitive advantage.

Reviews

There are no reviews yet.