Description

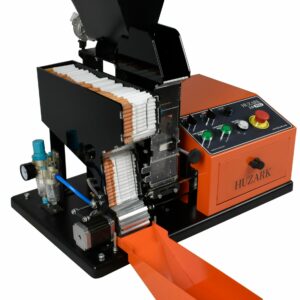

Cigarette Filling Machine

Direct Offer from Polish Manufacturer Huzark®

- Complete Solutions for Compact Cigarette Factories

- Refined Machine

- Service in Poland

- Spare Parts Readily Available

Our cigarette filling machine has a production capacity of 80 cigarettes per minute, with three operating modes: 40/60, and 80 cigarettes per minute, allowing for the production of up to 24 cartons per hour. It is designed for filling filtered tubes cigarette of 8mm and a filter length of 15mm, making it compatible with standard KingSize tubes.

Key features include:

- Smooth Adjustment of Tube Density: Achieve precisely the type of cigarette you desire.

- Large Capacity Hopper: Holds up to 800 tubes.

- Adjustable Tube Shaking Mechanism: Ensures perfect alignment of tubes.

- Noise Reduction: The cigarette filling machine operates quietly.

- Oil-Free Compressor Requirement: Needs an oil-free compressor working in the range of minimum 6 bar.

- Power Supply: 230V, compressed air minimum 6 bar.

- Weight: 45 kg.

- Dimensions: 70x70x44 cm.

The cigarette filling machine comes with a 12-month warranty, and we also provide post-warranty service.

Huzark Master – Our Latest and Fastest Cigarette Filling Machine

The Huzark Master features components that ensure the machine’s longevity and ease of use.

- Durable Blade: Made from exceptionally hard and robust steel.

- Enhanced Pressing System: Ensures the cigarettes resemble those found on store shelves even more closely.

The cigarette filling machine includes an innovative solution that allows for the preference of tobacco protruding from the tube or flush with the end of the tube (Program I and II).

- Automatic Tobacco Feeding: When the sensor detects a low tobacco level, it automatically feeds the material into the chamber.

The Best Quality to Price Ratio on the Market

Quick Return on Investment!

Our component selection focused on quality, resulting in a cigarette filling machine that stands unmatched.

- Durable Needle/Piston: The robust needle/piston for pushing tobacco can work intensively for a month, compared to Turkish models, which need replacement after about 30-40 cartons. The material is fully inserted.

- High-Quality Cigarettes: Cigarettes produced with our cigarette filling machine are scarcely different from store-bought ones.

- Versatility: Works with various types of materials – flake, pollack, and strips.

- Convenient: Equipped with a container for ready-made cigarettes, simplifying operation.

Being a Polish product, service and all parts are readily available.

Huzark Master – the ultimate cigarette filling machine

Stepping up to 80 cigarettes per minute is impressive on paper, but the true gain lies in consistency. Each cycle of the Huzark Master compresses tobacco with micron‑level accuracy, producing a burn rate that rivals premium factory brands. For operators who demand uniformity across thousands of sticks, this is the professional cigarette making machine that delivers day in, day out. Mastering your production is easy and at hand with Huzark Master.

Built‑in intelligence for fast and lean production

A laser sensor inside the feed chamber monitors density in real time. If it detects a deviation, the machine auto‑corrects piston pressure before the next cycle – no stop‑and‑start adjustments required. This closed‑loop control keeps waste below 1%! It saves both tobacco and casings. Each time, cycle by cycle. You save even more with Huzark Master.

Everyday advantages of this cigarette filler

- Rapid changeovers – store up to five tube‑density profiles in memory; switch recipes with one touch.

- Ergonomic hopper design – the 800‑tube magazine tilts forward for easy loading, reducing operator fatigue.

- Quiet, oil‑free operation – Pairing with a 6‑bar oil‑free compressor protects flavor integrity while keeping noise under 70 dB.

Compact footprint, industrial output

At 70 × 70 × 44 cm, the Huzark Master occupies less than half a square meter yet produces up to 24 cartons per hour. Add a second unit in parallel and double capacity without re‑engineering your floor plan. It’s as easy as building something with Lego bricks – but it’s about bringing your cigarette production to the new level.

Faster ROI thanks to reliability

Every high‑stress component – blade, needle, piston – uses hardened Polish steel rated for a month of nonstop use. Fewer shutdowns mean quicker payback, often within the first year of operation. If service is required, local parts availability and remote‑diagnostic support get you back online fast.

Ready to upgrade your line?

When output, precision, and uptime are mission‑critical, the Huzark Master stands alone among modern cigarette filling machines. Talk with our team for more information – ask about financing options, or multi‑unit pricing and discover how effortless high‑volume production can be. Your next-level production is just one step away – just contact us.

Reviews

There are no reviews yet.