Description

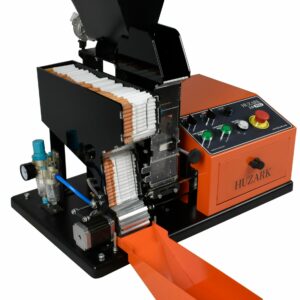

The Cigarette filling machine Huzark combines electric and pneumatic power sources, requiring an 8-bar compressor to function optimally. Crafted from premium stainless steel components, this machine boasts exceptional durability, ensuring a practically limitless service life.

Featuring three operational modes – single loading, and automatic modes I and II – our Injector stands out with its piston mechanism, ensuring flawless cigarette filling and supporting intensive use for up to a month. The resulting product closely mirrors those available in stores, ensuring consumer satisfaction.

Professional cigarette filling machine

Adaptability is a key feature of the Cigarette filling Machine Huzark, as it is designed to handle various types of tobacco. Additionally, the machine has been soundproofed to minimize noise disruptions in the production environment. Moreover, it includes a convenient tank for storing ready-made cigarettes, enhancing user convenience and workflow efficiency.

Diving deeper into the product specifications, the Cigarette filling Machine Huzark offers an efficiency of 50 pieces per minute. It is adept at injecting shell casings with filters, featuring a 15mm diameter and 8mm rolling size. The injection process is infinitely adjustable, allowing for precise customization to meet production needs. The shell casings tank has a generous capacity of 600 pieces, reducing the frequency of refills and optimizing workflow.

To ensure smooth operation, an 8-bar compressor is required for power, alongside a standard power supply of 230V and 8-bar compressed air. Despite its robust construction, the machine remains relatively lightweight at 35kg, with compact dimensions of 70x41x44cm, making it suitable for various production settings.

In summary, the Cigarette filling Machine Huzark combines durability, versatility, and efficiency, making it an ideal choice for manufacturers seeking high-quality and reliable cigarette production solutions.

Product Details:

- Efficiency of 50 pieces per minute

- Adapted to inject the shell casings with filter, 15mm, rolling: 8mm

- Infinitely adjustable shell casings injection.

- Shell casings tank capacity: 600 pieces

- Soundproofed

- 8 bar compressor required

- Power: 230 v, 8bar compressed air

- Weight: 35kg

- Size: 70x41x44cm

The Huzark 2.0 – a professional cigarette making machine

Beyond its 50‑piece‑per‑minute speed, the 2024 model delivers industrial‑grade repeatability – exactly what a modern professional cigarette making machine must offer. Every stroke of the stainless‑steel piston packs tobacco evenly, so customers experience the same smooth draw in the first stick and the last. The result is fewer returns, stronger brand loyalty, and measurable savings on wasted materials.

Everyday gains with this cigarette filler

Because the hopper holds 600 tubes, one operator can supervise an entire shift without constant reloads. The sound‑dampened housing lowers ambient noise, making the production floor safer and more comfortable. Quick‑access panels give maintenance staff full reach of wear parts in minutes – to keep the cigarette filler online and your schedule intact.

Compressor‑friendly design

Already running shop air at 8 bar? Simply plug in the 230‑V line and connect the hose – no special wiring or extra regulators needed. That “drop‑in” setup shortens commissioning time, so the machine can start generating revenue almost immediately. No waiting, no additional costs – just profit from the first run.

Upgrade from a manual to an automated cigarette filling machine

Moving up from tabletop crank devices? The Huzark 2.0 replaces inconsistent hand rolls with perfect tube fills at the press of a button. Variable injection lets you fine‑tune density for different blends without tearing papers or clogging filters. It’s the easiest way to scale production and keep full creative control over flavor profiles.

Compact but scalable

At just 70 × 41 × 44 cm and 35 kg, the unit slides onto a workbench or movable cart, yet its stainless frame is rigid enough to run day after day. Add a second machine later, network them side by side, and double throughput with zero re‑engineering. With Huzark, you can scale up your production easily.

Ready for the next step in cigarette making?

If reliability, speed, and precision top your checklist for a cigarette filling machine, the Huzark 2.0 model 2024 answers every need. Contact our team for lead times, training packages, or multi‑unit discounts, and turn consistent 50‑per‑minute output into a lasting competitive edge.

Semi-Automatic Cellophane Wrapper – Cigarette Foil Wrapping Machine HUZARK COMBO

Semi-Automatic Cellophane Wrapper – Cigarette Foil Wrapping Machine HUZARK COMBO  Automatic Cellophoner for Packages for Cigarettes, Perfume etc.

Automatic Cellophoner for Packages for Cigarettes, Perfume etc.

Reviews

There are no reviews yet.